A number of faculty members from several different colleges at Augusta University have teamed up to produce face shields using 3D printing to help protect Augusta University Health clinical staff and patients from exposure to COVID-19.

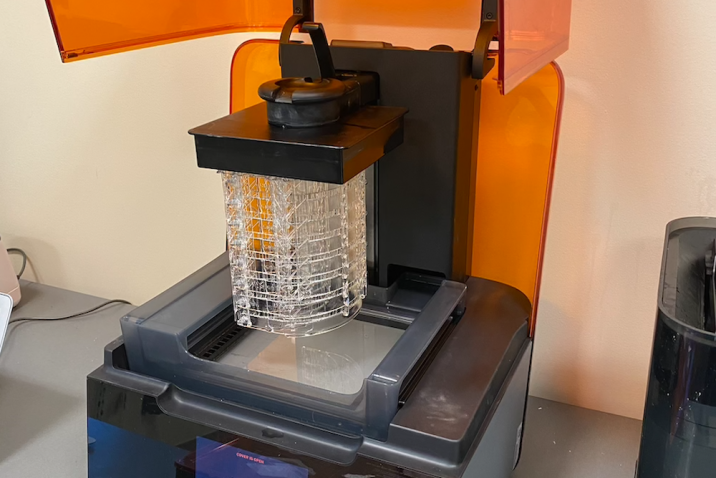

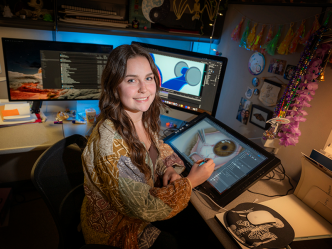

“Here at the Center for Instructional Innovation at Augusta University under Dr. Zach Kelehear, we do a lot of 3D printing,” said Lynsey Ekema, a board certified medical illustrator for the center. “We were told that researchers at Georgia Tech were working on developing different prototypes to create face shields and face masks for workers in Atlanta.”

Using 3D printers and laser cutting machines, the researchers at Georgia Tech have made at least 10,000 face shields, which protect clinicians’ eyes and faces from the coronavirus spread by the coughs and sneezes of the infected.

For the past two weeks, researchers have been working 16-hour days to crank out the easy-to-clean, reusable protective wear.

Ekema and her team at the Center for Instructional Innovation realized if mass producing face shields at Georgia Tech would work in Atlanta, the same type of effort could be successful in Augusta as well.

They teamed up with Dr. Sarah Long, director of research operations, and Dr. Michael Diamond, senior vice president for research at Augusta University, to see how they could provide proper protective gear to the clinical staff.

The first step was finding out who had 3D printers available on campus or in the Augusta area that could be utilized to help develop the face masks.

“I got in touch with Cheryl Goldsleger, the Morris Eminent Scholar in Art at Augusta University, and Bill Gray, the manager of educational technology at the College of Education, because we all have 3D printers and we know each other,” Ekema said, adding that they went over the different patterns and files available for printing medical protective wear and began making a few different prototypes. “I contacted Mallary Myers, the vice president and chief innovation officer for Augusta University Health, and told her that we have a couple of face shields and prototypes of masks that we have printed. I explained, ‘These are all reusable models that you could use in the hospital. The great thing about these face masks, if you properly sterilize them, they can be used again.’”

As soon as Gray from the College of Education heard about the project, he was immediately on board.

“The benefit of 3D printing in situations like this is that it allows for rapid prototyping,” he said. “I don’t think the design for this has been out for more than a week and already it’s being disbursed worldwide. Anyone with a 3D printer can download the model and print face shields and masks. So, all the help that can be had is needed.”

Scott Thorp, the chair of Augusta University’s Department of Art and Design, and Amanda Behr, program director and associate professor of the Department of Medical Illustration, also joined the effort in creating the masks and shields.

Goldsleger said developing these face shields for the clinical professionals has been an amazing experience.

“Lynsey (Ekema) and I have similar Formlabs 3D printers, only she has a newer model with a slightly bigger build volume,” Goldsleger said. “Together, we have figured out how to max out the number of face shield parts we can build at one time by stacking them on the print bed. She has really done a remarkable job getting the face shield design approved by the hospital. For me, this has been a really rewarding project to work on.”

Currently, many hospitals around the country are in desperate need of N95 respiratory masks amid the coronavirus pandemic.

“The problem is a lot of the N95 masks have to be thrown away at the end of the day,” Ekema said. “And I think people are so desperate in other states for surgical masks and materials right now that they’re actually reusing them, which honestly kind of makes them useless.”

After reviewing the different prototypes of the face shields developed by the faculty and the community, Myers asked the team to create at least 1,000 face shields that could be used by the clinical staff at Augusta University Health.

“It’s actually remarkable and such a creative way to get some of our staff involved, using 3D printers that we already have to produce something that’s desperately needed to help perform patient care in the midst of this COVID crisis that we’re experiencing,” Myers said. “I’ve really been proud of the team. And it’s been amazing to see the different prototypes that they’ve provided.”

While there have been a few modifications made to the prototypes, Myers said she’s been extremely pleased with the proposed designs.

“Conceptually, the face shields work really well and it’s going to help us a great deal in the long run,” Myers said.

The team has also experimented developing what has been dubbed as the “Montana Mask,” which is a reusable plastic face mask designed for 3D printers by a college graduate and two medical professionals in Montana.

The design of that mask is still undergoing some modifications, Myers said.

Myers has also been overwhelmed by the support of the staff at Augusta University and the community coming together to help protect the clinical professionals from COVID-19 by developing these face shields.

“To me, what’s great about this community is that everybody wants to help and everybody cares about the caregivers and the frontline workers,” Myers said. “Having the community wanting to step up and make sure that they have the supplies they need is just wonderful. That’s really what makes Augusta so great.”

The only major obstacle currently standing in the team’s way is supplies.

“We are in need of photopolymer resin and rubbing alcohol of 70% or higher,” Ekema said. “We have made a push to see if other companies have any excess resources sitting around out there, but we welcome any and all donations of those products.”

For an updated list of needed donations or how you can help, contact Lynsey Ekema at 706-446-1413 or get more information here.

Augusta University

Augusta University